Putting Sun at the heart of hydraulic regenerative braking systems

Lightning Systems (formerly Lightning Hybrids) is an innovative, forward-thinking company that saw an opportunity a few years back to bring hydraulic hybrid technology to medium- and heavy-duty fleet vehicles like shuttle buses, delivery vehicles and work trucks. Starting small in 2014 with 25 systems sold, the company has grown their hydraulic hybrid business substantially in four years, on track to sell more than 1,400 systems around the globe in 2018.

Their patented system works on the same basic principle as other parallel hybrid vehicle systems - capturing kinetic energy from braking, storing it and releasing it for acceleration during takeoff. But Lightning Systems does it with hydraulics, which is far better suited to heavy-duty vehicle applications than electric hybrids.

With this design, Lightning Systems captures that kinetic braking energy, using it to pump hydraulic fluid from the low-pressure to the high-pressure tank, storing the energy as hydraulic pressure. It then uses that energy during acceleration to drive a hydraulic motor, delivering torque to the vehicle’s drive shaft, which saves fuel and reduces emissions. Watch this animated video of the Hydraulic Regenerative Braking System at work.

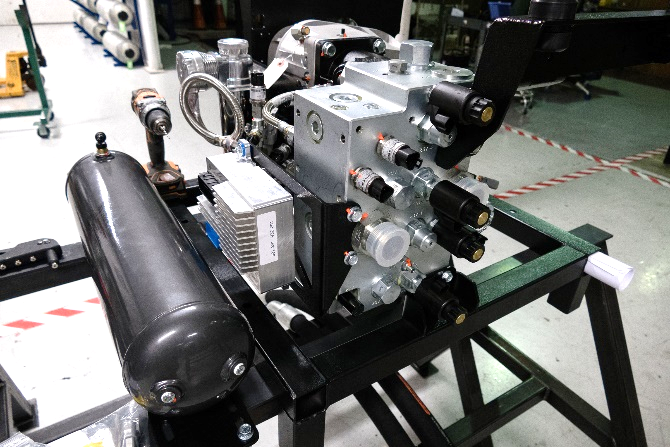

The hydraulics in the system are controlled by two custom-designed Sun Hydraulics manifolds using a range of Sun cartridge valves, including flow control, directional and solenoid-operated valves. The larger of the two manifolds handles the high-pressure logic functions while the smaller one is used for clutch control for their Power Transfer Module (PTM). In addition, this Lightning Systems design employs Sun valves elsewhere in the system to control the low-pressure accumulator.

The hydraulics in the system are controlled by two custom-designed Sun Hydraulics manifolds using a range of Sun cartridge valves, including flow control, directional and solenoid-operated valves. The larger of the two manifolds handles the high-pressure logic functions while the smaller one is used for clutch control for their Power Transfer Module (PTM). In addition, this Lightning Systems design employs Sun valves elsewhere in the system to control the low-pressure accumulator.

Why Sun?

Working with Sun’s team and with our local distributor, Hydraulic Controls, Inc., was a natural fit for Lightning Systems. After meeting their requirements for small-quantity, quick turnaround on the initial design, Sun continued to meet their needs and deliver a cost-competitive solution through multiple updates of the system.

Ian Patterson, Lead Hydraulics Engineer at the company, explains why they went with Sun:

Ian Patterson, Lead Hydraulics Engineer at the company, explains why they went with Sun:

“We choose to work with Sun Hydraulics for our hydraulic manifold designs because, like us, they’re innovators that relentlessly pursue quality in all aspects of their business. Sun’s engineers are constantly raising the bar in valve performance and implementing new, exciting valve technologies. Their lab technicians work diligently to accurately test key performance characteristics of each valve, and provide excellent customer support. To top it off, the manifold design services offered by Sun are some of the best and most creative in the business. For Lightning Hybrids, Sun Hydraulics isn’t just a supplier, but a partner helping us to take our business to the next level.”

With Sun’s manifolds and cartridges, Lightning Systems are able to save up to 35 percent in vehicle fuel costs, reduce output of toxic emissions by a minimum of 30 percent, increase the life of vehicles and create clean, regenerative energy. The end result is a system that offers multiple advantages over electric hybrid systems. In comparison to electric hybrids, these hydraulic systems last longer and are lighter, more efficient, safer, easier to maintain and less expensive – all positives for fleet owners and managers.

For more information on how Sun can provide smart solutions for your demanding applications, contact your local distributor.