Don't be afraid to get wet:

weatherized coil assemblies

Any electro-hydraulic coil-driven equipment exposed to harsh environments will benefit from this weatherized coil assembly. These assemblies protect electrically actuated, full-flow switching and electro-proportional cartridges, extending the coil's physical life and maintaining system reliability.

Any electro-hydraulic coil-driven equipment exposed to harsh environments will benefit from this weatherized coil assembly. These assemblies protect electrically actuated, full-flow switching and electro-proportional cartridges, extending the coil's physical life and maintaining system reliability.

Special Sun coils use the Metri-Pack 150 connector in conjunction with this simple-to-fit protective cover seal kit to survive more than 1000 hours in salt fog test, making this an ideal addition to any application subjected to full high-pressure wash-down or marine environments. These weatherized coils include a built-in TVS surge suppression diode and are available in 12, 14, 24, 28 and 36 Vdc. See our full line of weatherized coils and our weatherized seal kits.

The coil connector is rated to IP69K, making this the best choice for externally mounted coil protection and providing confidence in extended temperature operation under the most extreme conditions.

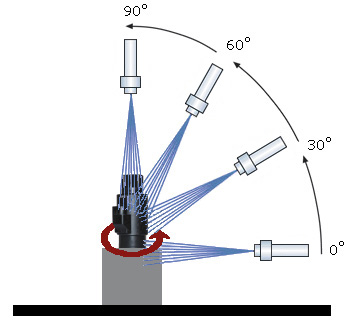

These weatherized coils require a spotface (see photo) on the sealing surface and therefore are best suited for new designs. Sun can provide integrated packages with appropriate cavities and spotface to accommodate the weatherized coils. And we offer several standard 90-degree manifolds with the spotface.

About IP69K

The IP69K code is an Ingress Protection Rating for high-pressure, high-temperature wash-down applications. The enclosures are not only dust tight, but must withstand high pressure and steam cleaning.

In addition to withstanding the IP69K testing requirements, Sun's weatherized cartridge assemblies have passed a 1000-hour salt fog test, ensuring corrosion resistance for marine applications.

For detailed information on Sun's rigorous testing process for weatherization, read our Environmental Test Specification.

Download a PDF of the article here >